“TRS Dental Lab strongly believe communication between the Dentist and the lab is paramount to successful treatment for the patient.”

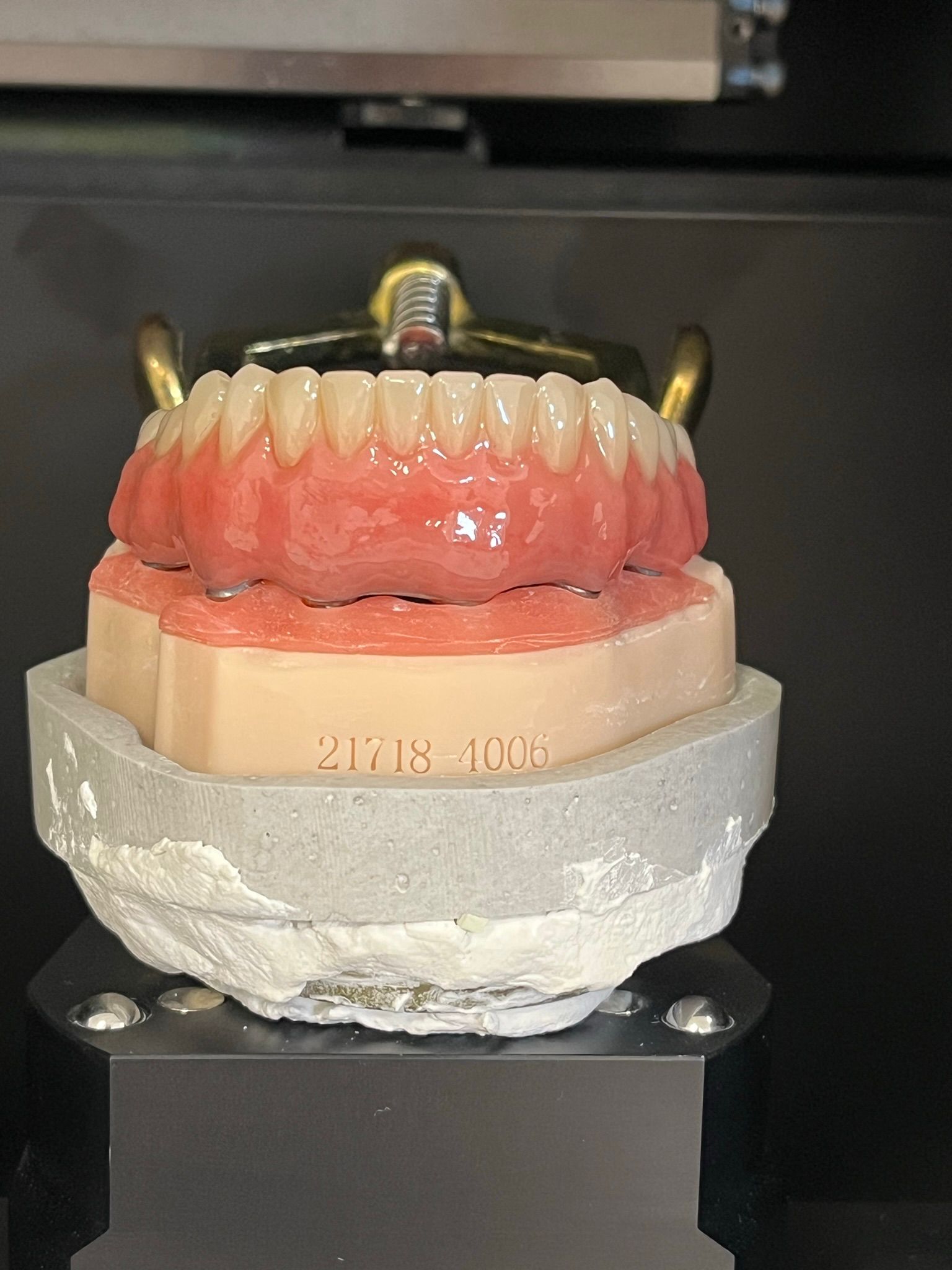

The Lucitone Digital Print Denture System

The Lucitone Digital Print Denture™ system is CAD designed and 3D printed via the Lucitone digital print denture base material and Lucitone IPN 3D premium teeth material by Dentsply Sirona, the first high-impact BAM (Body activated material) smart polymer technology.

The definition of body-activated material states that it will double its resistance to fracturing upon reaching body temperature which has been proven by independent studies. The amplified material properties resist breakage and prevent the worsening of any existing cracks or fractures.

Lucitone Digital Print Denture™ system can be used alongside traditional methods (impressions, bite rims etc) and digital methods (I/O scans from any intra oral scanner) with the result achieved as a 3D printed denture.

Benefits of Lucitone 3D print denture base material:

- 3D printed, consistently controlled via curing machines

- Minimum to no expansion rate

- High impact BAM (body-activated material)

- Exceeds ISO high impact & flexural strength standards

- Available in 5 Lucitone gingiva shades

- Colour stability of gingiva with no perceptible colour change

- Can be repaired and relined in the future

- Strong chemical bond with Lucitone IPN teeth.

Lucitone Digital Print Denture™ workflow:

Lucitone Digital Print Denture™ can be used in a traditional workflow with physical impressions and bite registrations rims, digitally via intra oral scans or the patient’s existing denture. We can modify the existing denture with a new fit surface, modify aesthetics and restore occlusal function if required.

The dentures are CAD designed within the parameters of the bite registrations and impressions of the anatomical landmarks. We design the denture based on the parameters of the anatomical landmarks of the impressions or I/O scan and separately design the teeth, with the aesthetics and function based on the parameters of the bite registration.

Once the CAD designed digital denture has been approved, we can either 3D print a try in or go straight to finish, as both teeth and the denture base are printed separately. STL files can be retained for future 3D printing without having to go through all the stages again depending on type of modification that is required e.g. new fit surface that would need an imp wash.